- Letter from the Board of Directors

- Management report

- Key figures

- Foundations for success

- Business model

- Strategy 2030+

- Risk management

- Stakeholders

- TCFD report

- Sustainability

- ESG governance

- Material topics and SDGs

- Economic impact

- Environmental impact

- Social impact

- Governance

- Corporate governance

- Board of Directors

- Management Board

- Additional information

- Remuneration

- Remuneration report

- Notes to the report

- CO reference table

- Statement by the Board of Directors

- GRI content index

- Due diligence and transparency

- Financial report 2024

- Vetropack Group

- Consolidated balance sheet

- Consolidated income statement

- Consolidated cash flow statement

- Changes in consolidated shareholders’ equity

- Consolidation principles

- Valuation principles

- Notes

- Ownership structure

- Company participations

- Alternative performance measures

- Five-year overview

- Vetropack Holding Ltd

- The materials we use to manufacture our glass containers are recycled glass, quartz sand, soda, lime, dolomite and feldspar, as well as colouring agents and coatings.

- We recognise the value of modern, energy-efficient production processes, and we manufacture our products in close proximity to our customers.

- Comprehensive testing and inspection processes ensure quality and safety.

- Our eight glassworks in seven countries position us close to our customers, with a maximum delivery radius of 400 kilometres.

- We offer technical customer service solutions – for challenges in the filling/bottling process, for example.

- Our (customised) glass packaging helps our customers to stand out from their market competitors.

- We make it possible for everyone to enjoy food and beverages in the most elegant, safest and most responsible way.

- We promote the circular economy by providing reusable and recyclable glass packaging.

- Recycled glass (cullet), quartz sand, soda, lime, dolomite, and feldspar

- Colouring agents such as iron, pyrite, chromite and selenium

- Coating materials

- Capital goods such as furnaces, glass-blowing machines, inspection machines and moulds

- Transport and distribution services

- Energy

Foundations for successBusiness model

Our business model supports a sustainable circular economy: this is because glass is largely manufactured from natural raw materials, and it can be reused and recycled an infinite number of times. Our corporate purpose is to make it possible for everyone to enjoy food and beverages in the most elegant, safest and most responsible way.

About Vetropack

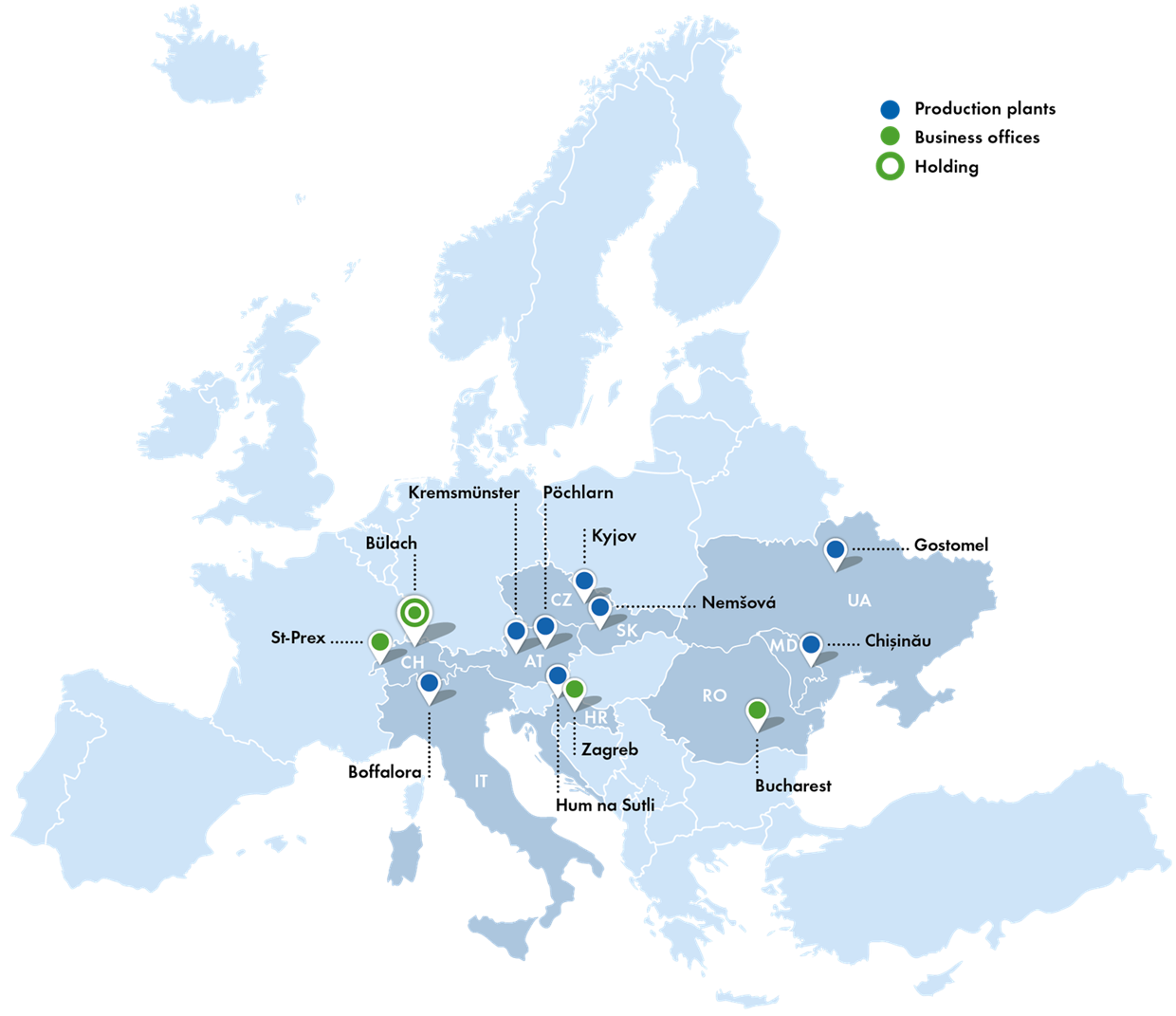

Headquartered at Bülach in Switzerland, the Vetropack Group employs a workforce of 3,585 people and numbers among Europe’s leading manufacturers of glass packaging for the food and beverage industry. We have eight glassworks, as well as sales and distribution locations in Switzerland, Austria, the Czech Republic, Croatia, Slovakia, Ukraine, Italy, the Republic of Moldova, and Romania.

31.12.2024 You can find detailed information about our organisation and locations on our website.

Our product portfolio comprises over 2,500 different glass containers in standard shapes as well as customised designs. We are active in Business-to-Business (B2B) commerce, and we supply around 1,700 customers in the food and beverage industry. The majority of our customers are located in Europe, within an average radius of 400 km from our glassworks. We produce approximately 5 billion glass containers each year. The breakdown of the various segments is as follows:

Development of process and product innovations and close collaboration with our customers are core success factors in our business model. In addition to standard products, for example, we develop personalised and distinctive glass packaging solutions. Our work always focuses on the quality and safety of our products.

We protect your enjoyment.

We are your partners throughout the entire product life cycle.

1Raw materials

The materials we use to manufacture our glass containers are recycled glass, quartz sand, soda, lime, dolomite and feldspar, as well as colouring agents and coatings.

2Melt and mould

We recognise the value of modern, energy-efficient production processes, and we manufacture our products in close proximity to our customers.

3Check

Comprehensive testing and inspection processes ensure quality and safety.

4Pack and deliver

Our eight glassworks in seven countries position us close to our customers, with a maximum delivery radius of 400 kilometres.

5Fill

We offer technical customer service solutions – for challenges in the filling/bottling process, for example.

6Sell

Our (customised) glass packaging helps our customers to stand out from their market competitors.

7Enjoy

We make it possible for everyone to enjoy food and beverages in the most elegant, safest and most responsible way.

8Return or recycle

We promote the circular economy by providing reusable and recyclable glass packaging.

We are your partners throughout the entire product life cycle.

Our value chain

Raw materials and suppliers

To manufacture our glass packaging, we use the following raw materials (among others):

Important assets and commodities for our production include:

We have around 5,000 direct suppliers and all of them are located in Europe. They include about 429 strategic suppliers. They provide products and services for our entire Group. We operate seven cullet processing plants of our own. Thanks to them, we are able to increase the availability of high-quality cullet and use it as a starting material for new products.

Glass production

We are committed to modern production processes, and we recognise the value of energy-efficient production in proximity to our customers. To manufacture glass, we melt the raw materials at temperatures of around 1,600°C. Shears cut the glass gobs, which are then moulded into the desired shape in the glass-blowing machines. The moulded products are slowly cooled and tempered to give them their strength. Before our glass containers are packaged and sold, they undergo extensive mechanical and manual quality controls. Management systems and certifications guarantee high product quality and product safety. We pack the finished products on pallets for transportation.

Products and services

As well as manufacturing our glass packaging for the food and beverage industry, we offer our customers a wide range of services as part of our Service plus+ approach. These include consulting and support in various areas: packaging analysis, filling/bottling and closure technology, glass finishing, and labelling. Our technical customer service provides support from the very start of the development process for new glass packaging. Our service team can also measure the forces acting on the glass bodies during filling, with the help of a sensor. Based on this information, our customers can adjust their filling processes optimally so as to reduce the risk of glass breakage.

Our product portfolio comprises glass packaging for beers and ciders, wines, spirits, soft drinks and foods. Our wide-neck jars, for instance, are ideal for preserving fruit and vegetables. Other highlights of our portfolio include jars for spreadables such as jam, and honey, jars for meat and fish, bottles for vinegar and oil, bottles and containers for sauces and dairy products, as well as containers for baby food. Our customers can access all our glass packaging products in our online catalogue by searching for criteria such as filling volume, shape, colours or closure types.

One of our most important products is our thermally tempered lightweight glass bottle. The glass bottle produced with this innovative process is around 30 percent lighter than a standard bottle – but, at the same time, more resistant to abrasion. These lightweight yet robust glass bottles are already in use as reusable bottles, and they are set to become even more relevant as a result of the EU’s Packaging and Packaging Waste Regulation (PPWR).

Customers and consumers

Glass packaging enables people to enjoy food and beverages in the most elegant, safest and most responsible way. We view glass as a sustainable packaging material – because it is reusable and recyclable. Glass is inert, and it is manufactured without substances that are harmful to health – so it provides optimal protection for the foods and ensures their shelf life. Another reason why glass packaging is gaining in popularity is that it does not impair the taste and quality of the beverages and foods it contains. We describe further health-related and environmental advantages of glass here.

Our customers range from multinational corporations to small manufacturers in the food and beverage industry. Our corporate website showcases various successful collaboration partnerships with our customers that have lasted many years.

Consumers can purchase food and beverages in our glass packaging from retailers and wholesalers, or enjoy them in catering trade outlets. We assume that the majority of consumers are located in Europe, but products such as wine bottles are also exported to other continents. For this reason, we do not have any more precise information on the geographical breakdown of our consumers.

End-of-life and recycling

The local glass collection infrastructure, legislation and consumer behaviour are factors that determine what happens to our glass containers after they have been used. In Europe – our largest sales market – glass collection rates vary sharply, as the study by the Close the Glass Loop initiative shows. As a member of the European Container Glass Federation (FEVE), we raise public awareness about the relevance of glass collection. Alongside factors such as cost, transport systems and export behaviour, the glass collection rate also influences the availability of cullet and, consequently, the mix of raw materials in new products.

- Vetropack Group

- Corporate governance

- Governance

- Social impact

- Environmental impact