- Letter from the Board of Directors

- Management report

- Key figures

- Foundations for success

- Business model

- Strategy 2030+

- Risk management

- Stakeholders

- TCFD report

- Sustainability

- ESG governance

- Material topics and SDGs

- Economic impact

- Environmental impact

- Social impact

- Governance

- Corporate governance

- Board of Directors

- Management Board

- Additional information

- Remuneration

- Remuneration report

- Notes to the report

- CO reference table

- Statement by the Board of Directors

- GRI content index

- Due diligence and transparency

- Financial report 2024

- Vetropack Group

- Consolidated balance sheet

- Consolidated income statement

- Consolidated cash flow statement

- Changes in consolidated shareholders’ equity

- Consolidation principles

- Valuation principles

- Notes

- Ownership structure

- Company participations

- Alternative performance measures

- Five-year overview

- Vetropack Holding Ltd

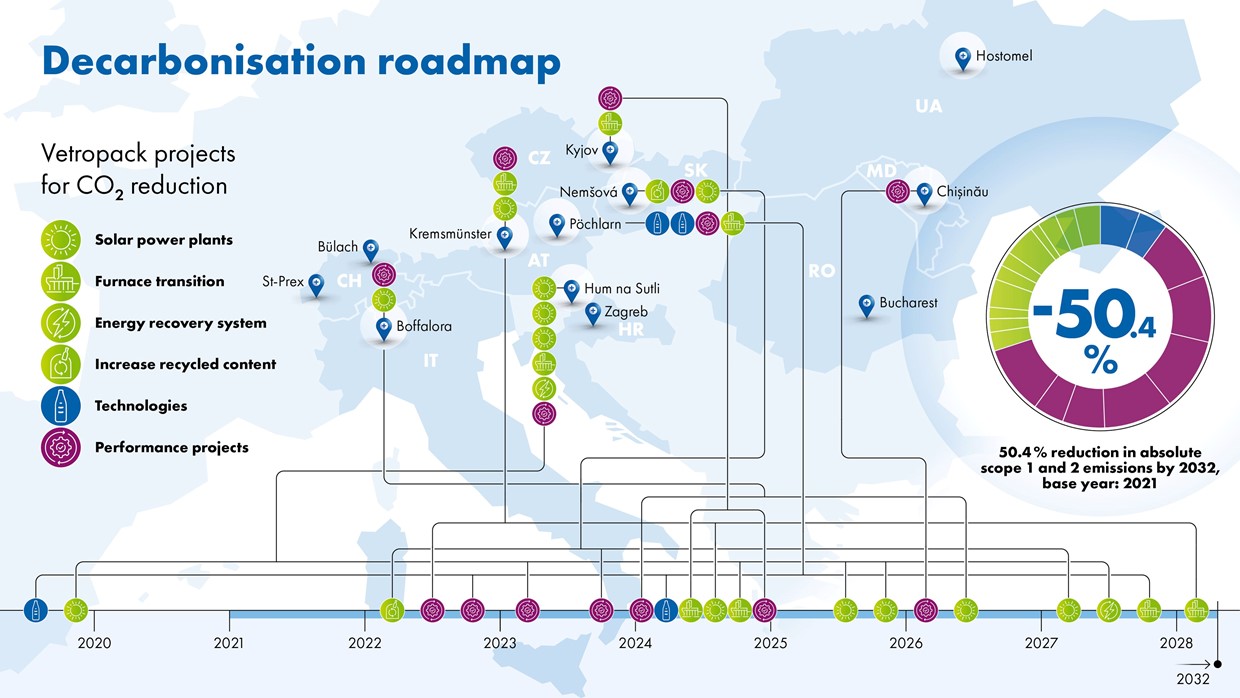

- Climate targets validated by the Science Based Targets initiative (SBTi)

- Reduce absolute Scope 1 and 2 greenhouse gas emissions 50.4 percent by 2032 from a 2021 base year

- Reduce absolute Scope 3 greenhouse gas emissions (categories purchased goods and services, capital goods, fuel- and energy-related activities and upstream transportation and distribution) 30 percent by 2032 from a 2021 base year

- Decarbonisation roadmap to achieve our climate targets

- Commissioning of a new furnace with higher performance in Kyjov

- Modernisation of a furnace and commissioning of a servo-electrically driven NIS glass forming machine in Hum na Sutli

- Installation of photovoltaic systems in Kremsmünster and Hum na Sutli

- 50.4 percent reduction of absolute Scope 1 and Scope 2 GHG emissions by 2032 as compared to a 2021 base year

- 30 percent reduction of absolute Scope 3 GHG emissions (categories purchased goods and services, capital goods, fuel- and energy-related activities, and upstream transportation and distribution) by 2032 as compared to a 2021 base year.

- Source 100 percent renewable electricity (throughout our entire operations) by 2032

- Furnace repairs and construction of new furnaces give us major leverage to make more efficient use of the natural gas required for the melting processes. This is because the refurbishment of furnaces can improve energy efficiency by 10 to 15 percent. Our scope for action here depends on the technology available on the market.

- Progressively electrifying our furnaces: increasing the share of electrical energy used to operate the furnaces. This is mostly possible with latest-generation furnaces.

- Using the highest possible share of renewable electricity (through sourcing, or from our own production)

- Participation in research projects under the auspices of International Partners in Glass Research (IPGR). Focal points here are optimising the composition of raw materials for glass production, and testing new furnace technologies.

- Using the highest possible share of recycled glass as a raw material for manufacturing new glass packaging. According to information from the European Container Glass Federation (FEVE), utilising 10 percent of used glass results in savings of about 2.5 percent on energy and 5 percent on CO2 emissions as compared to glass production without the addition of cullet. More information on this aspect is available in the Resources section.

- New vehicles in our own vehicle fleet must be electric or hybrid.

- Switching to electrically-powered forklifts

- Performance Improvement Programme (PIP): planning optimal utilisation of melting furnace capacity for efficient energy usage, and reducing the quantity of soda required. More information is available in the Economic performance section.

- Rightweighting: our glass containers consist of only as much material – and weigh only as much – as is necessary to meet the customer’s specifications and requirements without causing unnecessary environmental pollution due to excessive use of raw materials. More information is available in the Resources section.

- Modernisation of the furnace at Hum na Sutli (Croatia) in 2024

- Consolidation of two furnaces at Kremsmünster from 2028 onwards: by combining the two furnaces to create one large furnace, we will increase capacity and improve energy efficiency. The modernised furnace should largely be operated with electricity, so it could enable us to halve the CO2 emissions from the furnace.

- Use of energy we produce ourselves thanks to the installation of photovoltaic systems on our roofs – for example at Kremsmünster (Austria) and at our Croatian plant, Vetropack Straža d.d.

“

The consequences of climate change demand immediate collective action. Given the high energy demand in the glass industry, we must meet our responsibilities and engage in active climate protection.

Nicolas Lootens, Group Sustainability Manager

SustainabilityClimate protection

Climate protection presents challenges in our industry because large quantities of energy are required to manufacture glass packaging, and the process of melting the raw materials generates CO2 emissions. We are addressing these challenges with our climate targets, which were validated by the Science Based Targets initiative (SBTi) in the reporting year. Vetropack’s most important climate protection measures include technical optimisation and electrification of our furnaces, renewable electricity sourcing and own production, reducing the percentage of soda, and increasing the share of recycled glass in the mix of raw materials.

The glass packaging industry is very intensive in terms of energy and greenhouse gases. Temperatures of around 1,600°C are required to melt the raw materials, and large quantities of natural gas are currently used for this purpose. Greenhouse gases are also generated in the supply chain from the production and extraction of the raw materials (including soda as the largest source of emissions), and also by transport processes. On the other hand, Vetropack is increasingly confronted with climate-related transition risks and physical risks. Climate-related transition risks include regulatory changes such as the EU Packaging and Packaging Waste Regulation (PPWR), or market risks such as rising and fluctuating energy prices. The main physical risks we identify are the growing shortage of water and the increase in temperatures. Our TCFD report describes how climate-related risks and opportunities impact our business model, and how we are reducing climate risks and making strategic use of climate-related opportunities.

Concepts, policies and measures

Environmental policy and responsibilities

Vetropack’s Health, safety and environmental policy governs the Group-wide approach to climate and environmental protection. This policy includes employee training aimed at promoting awareness of climate and environmental protection. Our Group Sustainability Manager develops Vetropack’s climate targets and the Sustainability Steering Committee approves them. The TCFD report gives a detailed description of our climate-related responsibilities at the various hierarchical levels. It also explains how we integrate climate-related opportunities and risks into our risk management.

Science Based Targets initiative (SBTi) and decarbonisation roadmap

Climate protection is an integral element of our Clearly sustainable strategic thrust. We are committed to effective climate targets in keeping with the Paris Agreement on Climate Change, and we undertake to implement a science-based emission reduction pathway. The Science Based Targets initiative (SBTi) validated our climate targets in the year under review:

To implement the targeted emission reduction pathway, we are putting these climate protection measures into practice:

We achieve our climate targets with the help of the decarbonisation roadmap shown here.

Decarbonisation roadmap We are currently focusing on these projects:

Our suppliers’ Scope 3 emissions and commitment to climate protection

Scope 3 accounts for more tha 50 percent of Vetropack’s total emissions. The main categories involved are purchased goods and services, fuel- and energy-related activities, upstream transportation and distribution, downstream transportation and distribution and capital goods. We are taking several measures to reduce our Scope 3 emissions: we are minimising the soda content, collaborating with the manufacturers to recycle our moulds and fire-resistant materials, and we are also testing new packaging film made of recycled material. We can only reduce upstream Scope 3 emissions in collaboration with our suppliers. In view of this, our first step was to determine the status quo regarding our suppliers’ commitment to climate protection. For this purpose, we conducted a survey and organised webinars. Our goals here were twofold: to communicate our commitment to climate protection, and to create awareness of this issue. The evaluation of this analysis is a key element of our future emission reduction strategy. More information on this aspect is available in the Supply chain management section.

Progress and events in the reporting year

Efficiency gains thanks to new furnace in KyjovWe commissioned the new furnace at our Czech site in Kyjov at the start of 2024. The rebuilt furnace offers greater production capacity, so there is an impressive increase in the efficiency of its energy usage. In addition, two servo-driven NIS glass-blowing machines and an AIS glass blowing machine were commissioned. Servo technology not only results in exceptionally precise glass forming processes, but also delivers a convincing reduction in energy consumption and remarkable improvements in efficiency and performance. The NIS machine requires less human interaction, so it increases safety in production. Also see: Occupational health and safety.

Vetropack Straža d.d. implements modernisation measures to benefit climate protectionThe flint furnace at our Croatian plant in Hum na Sutli was drained and then demolished in September 2024. After reconstruction, production was ramped up again in December. As part of this project, Vetropack Straža d.d. also introduced new glass-blowing machines. One of these is a servo-electrically driven NIS glass-blowing machine that features exceptionally efficient energy usage. Thanks to this modernisation, the plant achieves higher performance and optimises its production costs.

Photovoltaic systems in KremsmünsterWe are installing photovoltaic systems on the roofs of our Kremsmünster plant in a multi-stage project that will continue until 2026. To ensure that almost 100 percent of the generated electricity is channelled directly into production, the entire system is tailored to the plant’s electricity consumer profile. The first stage of expansion began in 2023, and we completed the second stage in the reporting year. By the time the project is completed in 2026, the system will produce around eight megawatt hours of solar power, approximately equivalent to the annual consumption of 2,000 households. After the final expansion stage, this means we will save around 345 metric tons of CO2 per year.

Photovoltaic systems in Hum na SutliVetropack Straža d.d. has made a start on installing the third photovoltaic system. After completion of the project, we expect it will be possible to reduce CO2 emissions from the plant by around 300 metric tons per year. The project is scheduled to take 11 months and is set to comprise around 4,483 photovoltaic modules.

Performance indicators

Energy consumption

Change

2024

in %

2023

in %

Total energy consumption in GWh

0%

2 752

2 747

Electricity

12%

486

18%

433

16%

Natural gas

– 2%

2 253

82%

2 299

84%

Other (Heating oil, diesel, petrol…)

– 6%

13

0%

14

0%

Specific energy consumption in MWh/t 1)

– 4%

1.90

1.97

1) Per metric ton of glass produced that satisfies all quality and safety requirements thus qualifying for sale.

Due to a higher ‘boosting share’ (the percentage of electricity used compared to natural gas) at our site in Boffalora, Vetropack's electricity consumption increased between 2023 and 2024. However, the Group’s specific energy consumption decreased by 4 percent between 2023 and 2024: this reflects improved production efficiency at Boffalora (with efficiency gains of 23 percent between 2023 and 2024). On our sites in Kremsmünster, Pöchlarn, Kyjov and Gostomel have also achieved efficiency gains.

Greenhouse gas emissions Scope 1 and Scope 2

Change

2024

in %

2023 4)

in %

Scope 1 + 2 greenhouse gas emissions in tCO 2 e 1)

3%

680 271

662 508

Scope 1 natural gas

– 2%

411 858

61%

421 510

64%

Scope 1 process emissions 4)

– 1%

113 385

17%

114 863

17%

Scope 1 other fuels and refrigerant leakages

33%

3 478

1%

2 625

1%

Scope 2 electricity 2)

23%

151 550

22%

123 511

19%

Specific greenhouse gas emissions in tCO 2 e/t 3)

– 0%

0.474

0.476

1) Greenhouse gas inventory calculated in accordance with the Greenhouse Gas Protocol. Emission factors used for the calculations of Scope 1 are from DEFRA 2024 for 2024 and DEFRA 2023 for 2023. Emission factors used for Scope 2 location-based are from IEA 2024 for 2024 and IEA 2023 for 2023.

2) Emissions for 2024 and 2023 are calculated according to the market-based approach (using energy certificates where available: these represent approximately 86% (2024) and 92% (2023) of overall electricity consumption). Applying the location-based approach results in 133,320 tCO2e for 2024 and 106,540 tCO2e for 2023.

3) Specific greenhouse gas emissions were calculated on the basis of Scope 1 and 2 emissions per metric ton of glass produced that satisfies all quality and safety requirements, thus qualifying for sale.

4) The process emissions reported in 2023 were erroneous due to a misreported value for soda consumption at one of our sites. The value reported previously was 104,921 tCO2e

Vetropack’s Scope 2 emissions increased between 2023 and 2024 due not only to higher electricity consumption, but also to an increase in market-based emission factors for purchased electricity in Austria and Italy.

Greenhouse gas emissions Scope 3

2023

in %

2022 2)

in %

Scope 3 greenhouse gas emissions in tCO 2 e 1)

712 260

500 578

1. Purchased goods and services

266 712

37%

142 468

28%

2. Capital goods

102 869

14%

62 965

13%

3. Fuel- and energy-related activities

94 565

13%

116 986

23%

4. Upstream transportation and distribution

135 809

19%

94 995

19%

5. Waste generated in operations

11 594

2%

6 546

1%

6. Business travel

1 068

0%

1 521

0%

7. Employee commuting

3 910

1%

4 362

1%

8. Upstream leased assets

3 475

0%

1 069

0%

9. Downstream transportation and distribution

60 834

9%

30 512

6%

10. Processing of sold products

6 142

1%

7 911

2%

11. Use of sold products

-

0%

–

0%

12. End-of-life treatment of sold products

25 191

4%

31 043

6%

13. Downstream leased assets

89

0%

192

0%

14. Franchises

-

0%

–

0%

15. Investments

2

0%

8

0%

1) Vetropack’s reporting of Scope 3 greenhouse gas emissions is delayed by a year.

2) Vetropack re-evaluated its Scope 3 emissions in 2024. This re-evaluation included changes in methodology: emission factors were updated and specified, input data for the calculation was refined. This means that the figures for 2022 and 2023 are not comparable.

For the 2023 year, we used more accurate emission factors to calculate our Scope 3 emissions. This led to a significant increase compared to previous years and, as a result, direct comparability with past data is not possible. For this reason, the present report does not include a comparative graph.

Total energy consumption by source 2024

in %

*less than 1% of the total energy consumption

Greenhouse gas emissions (Scope 1 + 2) by source 2024

in %

* market-based

Scope 3 emissions by category 2023

in tCO2e

Greenhouse gas emissions Scope 1 + 2

in tCO2e

* market-based

- Vetropack Group

- Corporate governance

- Governance

- Social impact

- Environmental impact