- Interview CEO

- Vetropack Locations

- Market environment offering opportunities and challenges

- Business model

- Strategy 2030

- Management Structure

- Organisation

- col2

- Material Topics and Performance Review

- Customers and suppliers

- Finances

- Innovation and intellectual property

- Production and products

- Employees

- Environment

- col3

- New Design

- Financial Report

- col1

- At a Glance

- Financial Report Vetropack Group

- Consolidated Balance Sheet

- Consolidated Income Statement

- Consolidated Cash Flow Statement

- Changes in Consolidated Shareholders’ Equity

- Consolidation Principles

- Valuation Principles

- Notes

- Ownership Structure

- Company Participations

- Report of the statutory auditor on the consolidated financial statements

- Five Year Overview

- col2

- Financial Report Vetropack Holding Ltd

- Balance Sheet

- Income Statement

- Notes

- Board of Directors’ (BoD) Proposal for the Corporate Profit Appropriation

- Report of the statutory auditor on the financial statements

- Five Year Overview

- Corporate Governance

- col1

- Introduction

- Board of Directors

- MB Members

- Remuneration and Additional Information

- Shareholders’ Participation Rights

- Auditors

- Information Policy

- General blocking periods

- Contact Address

- Remuneration Report

- col1

- Introduction

- Principles of the Remuneration Scheme and its Components

- Organisation and Authorities for Determining Remuneration

- Description of the Remuneration Components

- Board of Director’s Remuneration

- Management Board’s Remuneration

- Comparison of Remuneration disbursed with the Remuneration approved by the 2021 and 2022 Annual General Assembly

- Shareholdings

- Report of the statutory auditor on the remuneration report

- Sustainability Report

- col1

- Sustainability Report

- Customers and suppliers

- Finances

- Innovation and intellectual property

- Production and products

- Employees

- Environment

- col2

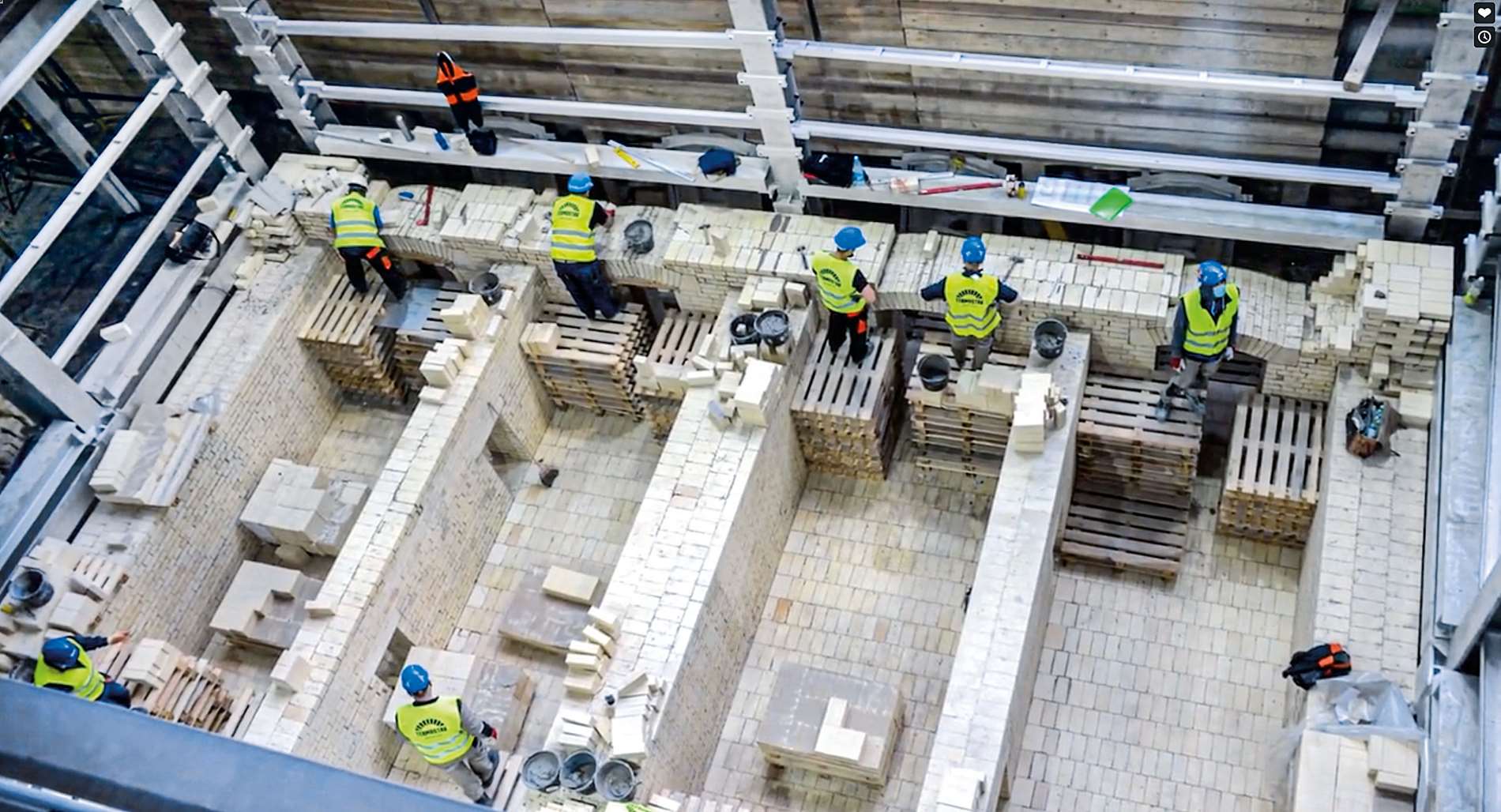

Furnace repair in Hum na Sutli

The next level of performance

The new coloured-glass production facility at the Croatian Vetropack plant in Hum na Sutli has not only resulted in a significant increase in capacity, but also allows for better working conditions, higher productivity and lower energy consumption. This strengthens the competitiveness not only of Vetropack Straža, but also of the entire Group.

The first glass drop left the furnace on 8 February 2021. This marked the end of a very intensive period – and huge investment – for Vetropack Straža. Before the furnace repair, the plant had undergone numerous infrastructural works, which involved major changes to the layout of the plant and the site plan of the entire plant premises.

In September 2020, the last and most important phase of this challenging project began by discharging the glass melt from the old furnace. The construction works took 8.5 weeks, during which time over 200 external workers were on site at the plant every day. Despite the highly complex organisation of the work and the special coronavirus restrictions which this project needed to comply with, the works were completed on time and without incident. The main contractor working on the project was Horn.

The new furnace has a larger capacity and an additional fourth production line. With three furnaces and twelve lines in total, Vetropack Straža currently achieves a capacity of 960 tonnes of glass containers per day. Despite the increase in capacity of the new furnace, its energy consumption is significantly less than its predecessor, which confirms Vetropack’s leading position in protecting the environment.

“A furnace repair is always a challenge. Due to the 2020 Covid-19 restrictions, the work was even more challenging than usual. Our colleagues in Hum na Sutli have done a fantastic job. Firing up the new furnace has elevated Croatia to the next level of performance. As a result of this investment project, the plant in Hum na Sutli will be able to produce roughly 1,000 tonnes of glass a day in future.”

Johann Reiter

CEO

- Sustainability Report

- col1

- col1

- col1

- col1

- Material Topics and Performance Review