- Challenges and market environment

- Business model

- Strategy

- Our focus: Clearly Sustainable

- Material topics and Sustainable Development Goals (SDGs)

- Governance structure

- Organisation

- Performance review

- col1

- Introduction to the performance review

- Customers and suppliers

- Finances

- Innovation and intellectual property

- Production and products

- Employees

- Environment

- Financial report

- col1

- At a glance

- Financial Report of the Vetropack Group

- Consolidated balance sheet

- Consolidated income statement

- Consolidated cash flow statement

- Changes in consolidated shareholders’ equity

- Consolidation principles

- Valuation principles

- Notes

- Ownership structure

- Company participations

- Report of the statutory auditor on the consolidated financial statements

- Five-year overview

- col2

- Financial Report of Vetropack Holding Ltd

- Balance sheet

- Income statement

- Notes

- Board of Directors’ (BoD) proposal for the corporate profit appropriation

- Report of the statutory auditor on the financial statements

- Five-year overview

- Corporate Governance

- col1

- Introduction

- Board of Directors

- Management Board

- Remuneration and additional information

- Shareholders’ participation rights

- Auditors

- Information policy

- Blocking period

- Contact address

- Remuneration report

- col1

- Introduction to the remuneration report

- Principles of the remuneration scheme and its components

- Organisation and authorities for determining remuneration

- Description of the remuneration components

- Board of Directors’ (BoD) remuneration

- Management Board’s remuneration

- Comparison of remuneration disbursed with remuneration approved by the Annual General Assembly

- Shareholdings

- Report of the statutory auditor on the remuneration report

- Sustainability report

Performance review

Customers and

suppliersActive stakeholder engagement

We believe that it is important to maintain close and regular exchanges with our stakeholders. By doing so, we learn at first hand what they require and expect from us; we become aware of relevant trends that could have a positive impact on our business, and we come to understand where our strengths lie and where we have potential for improvement.

We are mindful that our business is influenced by a large number of stakeholders. They include providers of funding (equity or borrowed capital), customers (primarily food and beverage manufacturers), suppliers (mainly of raw materials and plant), as well as employees or their representatives. We also include society in general among our stakeholder groups – represented by supervisory authorities, legislators, trade associations and non-government organisations. In the interest of long-term value creation, we maintain open and transparent dialogue with all these stakeholders. This is because active stakeholder management can have a positive impact on stakeholders' attitudes in general, and also towards Vetropack.

Our Code of Conduct and Business Ethics Policy set out the framework for our active engagement with stakeholders. We meet the regulatory requirements by publishing annual and semi-annual reports, and by holding annual general assemblies. We also communicate proactively about our strategic goals, and we publish a half-yearly financial report. The management at each of our various production sites is responsible for interacting appropriately with customers, employees, authorities and neighbours.

Both the CEO and the CFO maintain relationships with investors and are responsible for responding to their questions and enquiries. These exchanges take place at meetings or during plant visits. Other managers also share responsibility for maintaining relationships with stakeholders. For example, the CSCO, Head of Procurement and CTO are responsible for maintaining contact with suppliers.

As well as interacting with our customers on a daily basis, we conduct surveys at four-yearly intervals to learn about our customers' requirements and satisfaction levels; the last such survey took place in 2019. In view of the current situation, we are planning to conduct a customer survey next year.

Chapter customers and suppliersTo communicate with our extensive and diverse group of internal and external stakeholders, we make use of a varied range of communication media: the core channels are our company website, our intranet, our online employee magazine, brochures, our Vetrotime magazine for customers and – to a growing extent – LinkedIn as our preferred social media channel.

Vetropack Group websiteVetrotime customer magazineVetropack LinkedIn channelProgress and events in the reporting year

Constantly improving the transparency of our ESG reporting

ESG issues are constantly gaining importance for our customers. Packaging is a subject that attracts close attention from consumers as well as regulatory bodies, so our customers are increasingly approaching us with their requirements for information on this topic. We have substantially improved our transparency as regards ESG issues by creating the new position of Group Sustainability Manager. He communicates knowledge about practice-related ESG topics within the company, thus helping to raise our employees' awareness of these issues. This new specialised knowledge plays a particularly valuable part in our dialogue with customers: it allows us to provide expert explanations of Vetropack's ESG engagement, and it also helps us to develop solutions for problems in this area.

Responding to the challenges of the energy market through dialogue

The value of good communication often becomes apparent in crisis situations. During the year under review, our relationships with customers were put to the test by the unexpected and unpredictable developments on the energy market. Thanks to our engagement with our customers, underpinned by transparency and partnership, we were able to conduct the difficult discussions about the price increases related to energy costs on a basis of trust. The result was that we lost none of our customers. On the contrary: we firmly believe that relationships with our customers have been strengthened in the long term by our joint efforts to overcome this difficult situation.

Chapter multi-supplier strategyGap in social media communication closed

At Vetropack, we cultivate concise communication based on facts. This yields benefits for us in our communications with the capital markets. To reach additional stakeholder groups – including potential employees in particular – we want to offer more insights into everyday life at Vetropack, covering a variety of subjects; where appropriate, we would even like to initiate dialogue about these topics. To achieve this, we invested in active management of our LinkedIn channel during the year under review. The mix of official Group communications and posts by sites and their employees from all over Europe has proven successful for this purpose. Within one year, we have more than quadrupled the number of views (impressions) per month for our LinkedIn posts.

LinkedIn statistics: growth within one year

Impressions

You can find more information about stakeholder engagement in the following sections of this report:

Exchange with employees: employee engagementCollaboration with suppliers: multi-supplier strategyCustomer relationships: customer-specific productsMulti-supplier strategy

Collaboration with our suppliers is a core element of the new supply chain management system we established in the reporting year. By taking this step, we are pursuing a strategy based on having multiple suppliers in place for central resources. As well as ensuring our supplies of raw materials, equipment and plant, this multi-supplier strategy minimises risks in the supply chain.

Professional supply chain management is the foundation for a smooth flow of goods, so it provides the basis for economic efficiency and customer satisfaction. Recent years have seen global supply chains facing vast numbers of challenges that have highlighted the key part played by supply chain management in business success.

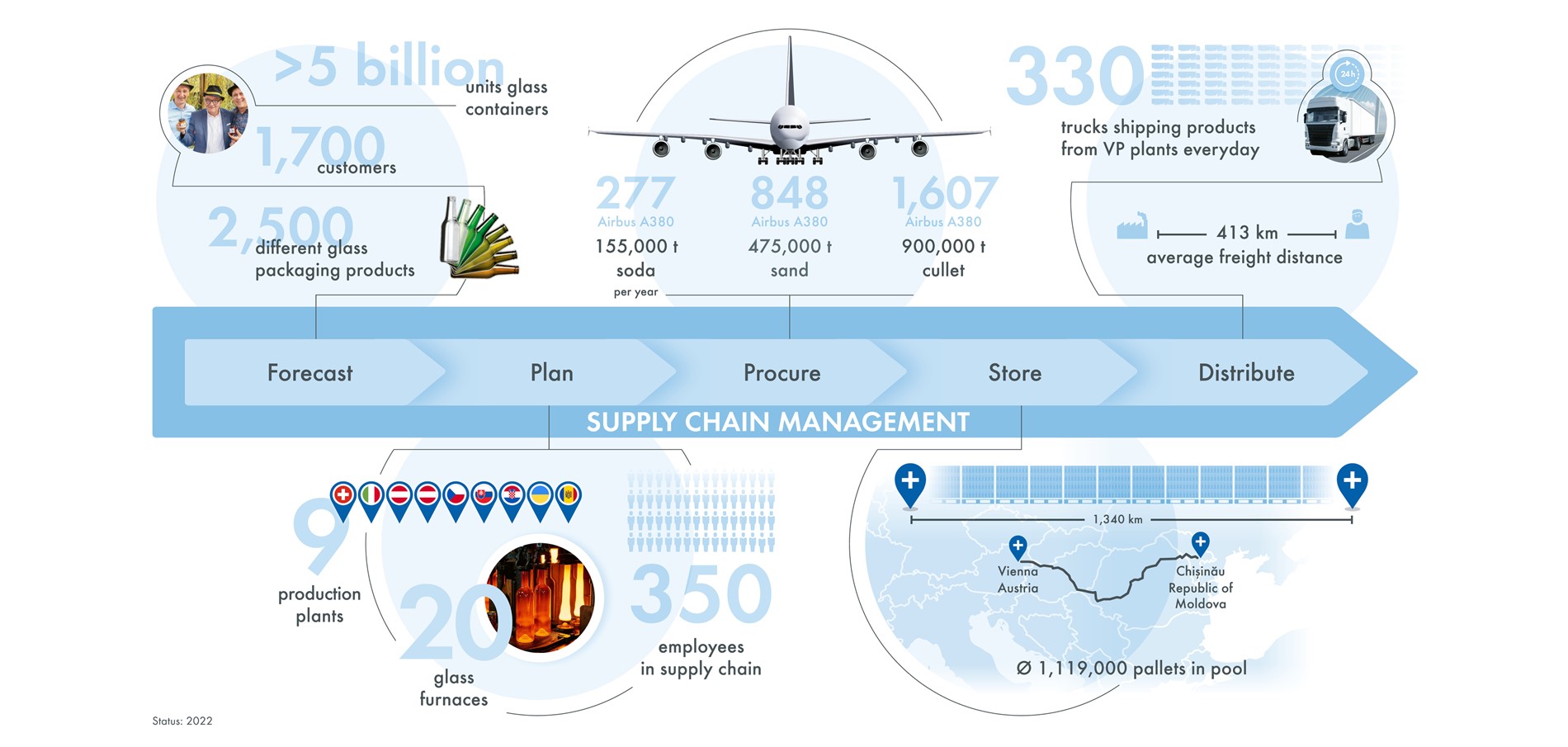

We too were aware that precise control of the supply chain, geared to resilience, is a valuable asset. This prompted our decision in 2021 to take various steps aimed at strengthening our supply chain management: these included positioning our Corporate Supply Chain Management at Group Management level. The supply chain management approach we implemented in 2022 (shown in the graphic below) is based on forecasts compiled in great detail, and it extends as far as warehousing and distribution.

The core element of our supply chain management is the procurement of the materials needed to manufacture over five billion glass containers each year. In specific terms, these amount to around 900,000 metric tons of cullet (used glass), 475,000 metric tons of sand, and 155,000 metric tons of soda. As well as these materials, we have to procure the machinery, plant, tools and energy needed to produce glass from them; we also have to ensure the provision of upstream and downstream services, especially in the transportation sector. To achieve these goals, our supplier management focuses on establishing, developing and maintaining partnerships with suppliers of energy and transportation services as well as primary and secondary raw materials. For goods and services of central importance, we implement a multi-supplier strategy based on the principle of multiple suppliers for central resources. By pursuing our multi-supplier strategy, we reduce the risk of interruptions to the production of glass packaging while supporting reliable deliveries of our products. Although this procurement strategy is initially more complex and costly, it ultimately offers the advantages of either reducing procurement costs or increasing the stability of the supply chain, depending on the market environment.

As part of our annual management reviews, we measure progress with the multi-supplier strategy on the basis of internal Key Performance Indicators (KPIs) such as the number of active suppliers per category and the number of long-term contracts in place.

Progress and events in the reporting year

Due to the severe pressure placed on Vetropack's supply chain by the war in Ukraine and the subsequent energy crisis, most of the new strategic and operative measures planned for the reporting year had to be extended into 2023.

Position of Chief Supply Chain Officer established

In 2021, Vetropack's Board of Directors decided to create a new position at Group level to focus on Corporate Supply Chain Management. On account of the acts of war in Ukraine during the year under review, however, the Chief Supply Chain Officer was not able to develop his area of responsibility to the extent originally planned. The majority of his activities were therefore focused on reducing the losses in Ukraine and managing the energy crisis.

Press release: «Board of Directors appoints Stephen Rayment as new Chief Supply Chain Officer at Group level» (17.11.2022)Maximum flexibility in energy procurement

Delays and interruptions to global supply chains presented a huge challenge for supply chain management in 2021, while energy prices in the reporting year were characterised by sharp increases and volatility. Natural gas is by far the most important source of energy, accounting for around 80 percent of the total. The rest of our energy demand is met by electricity. We leveraged the full scope of our flexibility in procurement and production here so as to keep the best possible control over cost increases and the risks of an energy shortage. To achieve this, we adopted a strategy comprising a mix of hedging and spot market transactions.

Supplier and capacity management following the shutdown of our Ukraine plant

The shutdown of our production in Ukraine meant that we lost significant capacities. To the best of our ability, we overcame the major challenges involved in fulfilling orders for customers who would normally be supplied from Ukraine. The suspension of production there also had a direct impact on our Group-level and local suppliers, some of whom saw unexpected losses of sales.

Long-term collaboration and shared basic values

Wherever possible, we endeavour to focus our collaboration on proven suppliers of many years' standing with whom we often share fundamental values. Sustainability issues are set to gain importance. In this context, we would like to hold our suppliers more accountable, but we aim in particular for commitment underpinned by a spirit of partnership. During the year under review, we created a dedicated position in Purchasing to develop this type of collaboration with our suppliers. The postholder maintains close dialogue with the Group Sustainability Manager.

Strong supplier base compensates for loss of Russian and Belarusian suppliers

Collaboration with suppliers in Russia and Belarus was terminated in the reporting year on account of the Ukraine war. We have been able to compensate for the elimination of these suppliers thanks to our extensive and proven supplier base.

Health and safety of customers and consumers

We supply the food and beverage industry with products used by millions of consumers, so we regard it as essential to ensure the health and safety of our customers – and of all consumers who use our products – at all times.

Packaging can have both positive and negative effects on the health and safety of everyone who comes into contact with it (including logistics personnel, customers and consumers, and many others). As a stable material that provides good protection for products, glass can help to improve safety during use as well as consumption. Because the weight of glass is comparatively high and it is relatively fragile, glass packaging entails certain risks; however, these can be minimised by adhering to established quality standards.

Being a «Leader in Quality» is a key objective in Vetropack’s Strategy 2030. Certified processes provide the basis for high quality and product safety. This is why we have set ourselves the goal of bringing all our business units into compliance with the ISO 9001 and ISO 22000 standards by 2023. At present, only three sites do not yet have the relevant certifications: Gostomel in the Ukraine (due to the current political situation), Trezzano in Italy (due to a change of plant), and Chișinău in the Republic of Moldova.

Quality and safety are essential factors that must be considered in every product development, according to clearly defined criteria. In our production, seamless quality testing is central to the safety of our products. Therefore, 100 percent of our glass containers are inspected to guarantee consistently high product quality and safety. This practice also ensures compliance with all legal and customer specifications.

To measure progress, we use quality indicators such as the number of complaints per glass container sold and the number of internally identified critical defects. For reasons of competitivity, however, we refrain from publishing these quality indicators.

Progress and events in the reporting year

Latest inspection technology in Croatia

Harmonisation and standardisation of quality assurance processes within the Vetropack Group continued again in 2022. Decisions on the testing technology used are planned and implemented on this basis. The goal is to ensure customer-specific quality requirements with the most efficient processes and the latest testing technology.

FSSC certification for innovative production technology

Echovai, the first returnable bottle made of tempered lightweight glass, is the next generation of returnable glass packaging. This innovative product is based on a special production technology that allows thermal hardening of glass bottles for the first time ever. Since the reporting year, an FSSC certification has proven the safety of this technology. This opens up access to additional markets for Echovai.

Further information on EchovaiDisclosures

GRI 416: Customer Health and Safety 2016

416-2 Incidents of non-compliance concerning the health and safety impacts of products and services

No incidents of non-compliance concerning the health and safety impacts of Vetropack’s products and services on customers were notified during the reporting period.

GRI 418: Customer Privavy 2016

418-2 Substantiated complaints concerning breaches of customer privacy and losses of customer data

There were no substantiated complaints during the reporting period.

- col1

- col1

- Financial Report of Vetropack Holding Ltd

- col1

- col1