- Interview CEO

- Vetropack Locations

- Market environment offering opportunities and challenges

- Business model

- Strategy 2030

- Management Structure

- Organisation

- Col2

- Material Topics and Performance Review

- Customers and suppliers

- Finances

- Innovation and intellectual property

- Production and products

- Employees

- Environment

- Col3

- New designs

- Financial Report

- Col1

- At a Glance

- Financial Report Vetropack Group

- Consolidated Balance Sheet

- Consolidated Income Statement

- Consolidated Cash Flow Statement

- Changes in Consolidated Shareholders’ Equity

- Consolidation Principles

- Valuation Principles

- Notes

- Ownership Structure

- Company Participations

- Report of the statutory auditor on the consolidated financial statements

- Five Year Overview

- Col2

- Financial Report Vetropack Holding Ltd

- Balance Sheet

- Income Statement

- Notes

- Board of Directors’ (BoD) Proposal for the Corporate Profit Appropriation

- Report of the statutory auditor on the financial statements

- Five Year Overview

- Corporate Governance

- Col1

- Introduction

- Board of Directors

- MB Members

- Remuneration and Additional Information

- Shareholders’ Participation Rights

- Auditors

- Information Policy

- Contact Address

- Remuneration Report

- Col1

- Introduction

- Principles of the Remuneration Scheme and its Components

- Organisation and Authorities for Determining Remuneration

- Description of the Remuneration Components

- Board of Director’s Remuneration

- Management Board’s Remuneration

- Comparison of Remuneration disbursed with the Remuneration approved by the 2020 and 2021 Annual General Assembly

- Shareholdings

- Report of the statutory auditor on the remuneration report

- Sustainability Report

- Col1

- Sustainability Report

- Customers and suppliers

- Finances

- Innovation and intellectual property

- Production and products

- Employees

- Environment

- Col2

Vetropack Austria

Renovating the white glass line at the Pöchlarn plant

The replacement of the white glass line at the Pöchlarn plant took just 28 days to complete. On the one hand, the comprehensive modernisation boosts line utilisation and expands white glass production capacities. On the other, it provides improved ergonomic conditions for the line staff and, not least, increased occupational safety.

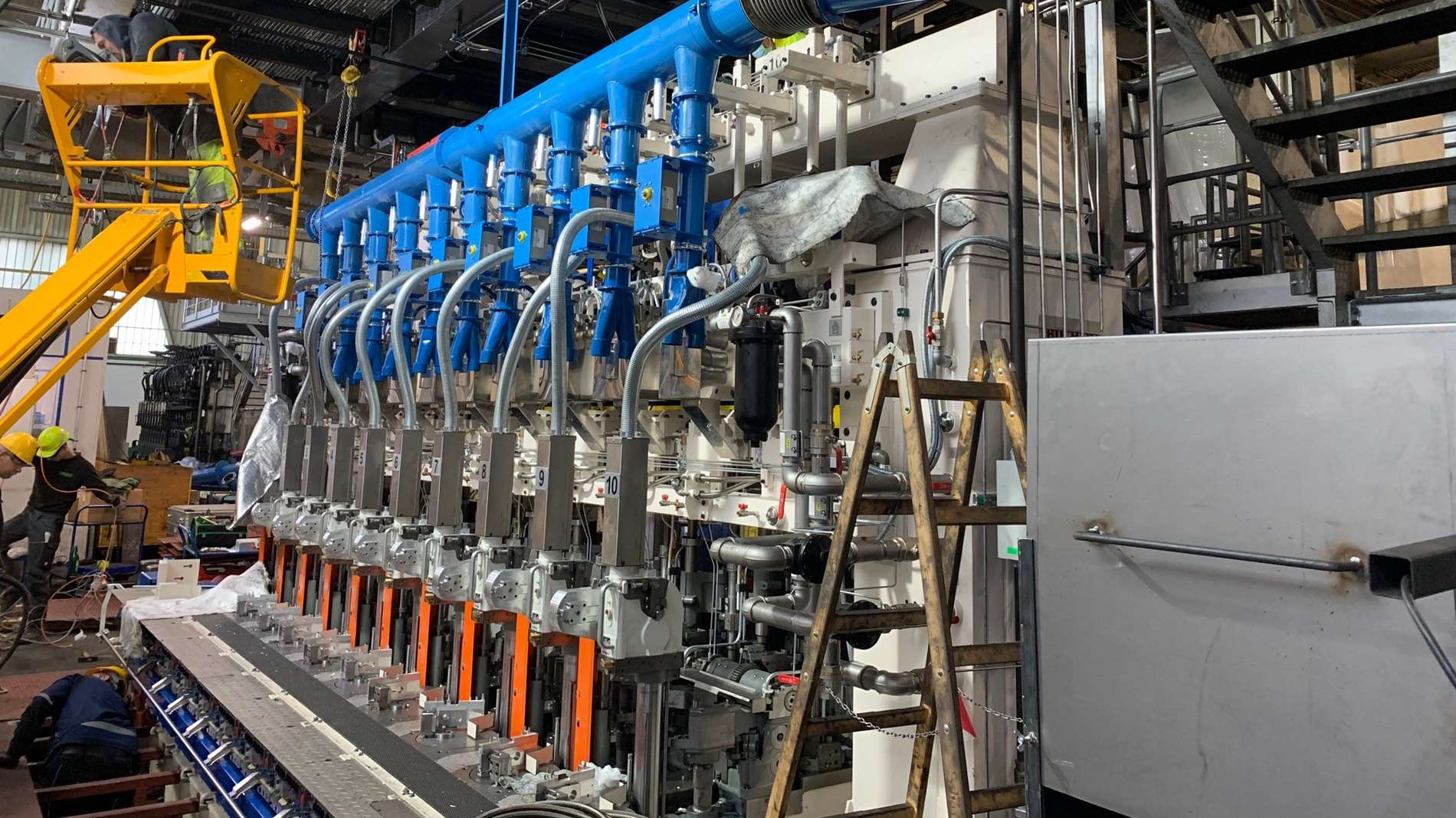

Delivery of the new production machine

Substructure

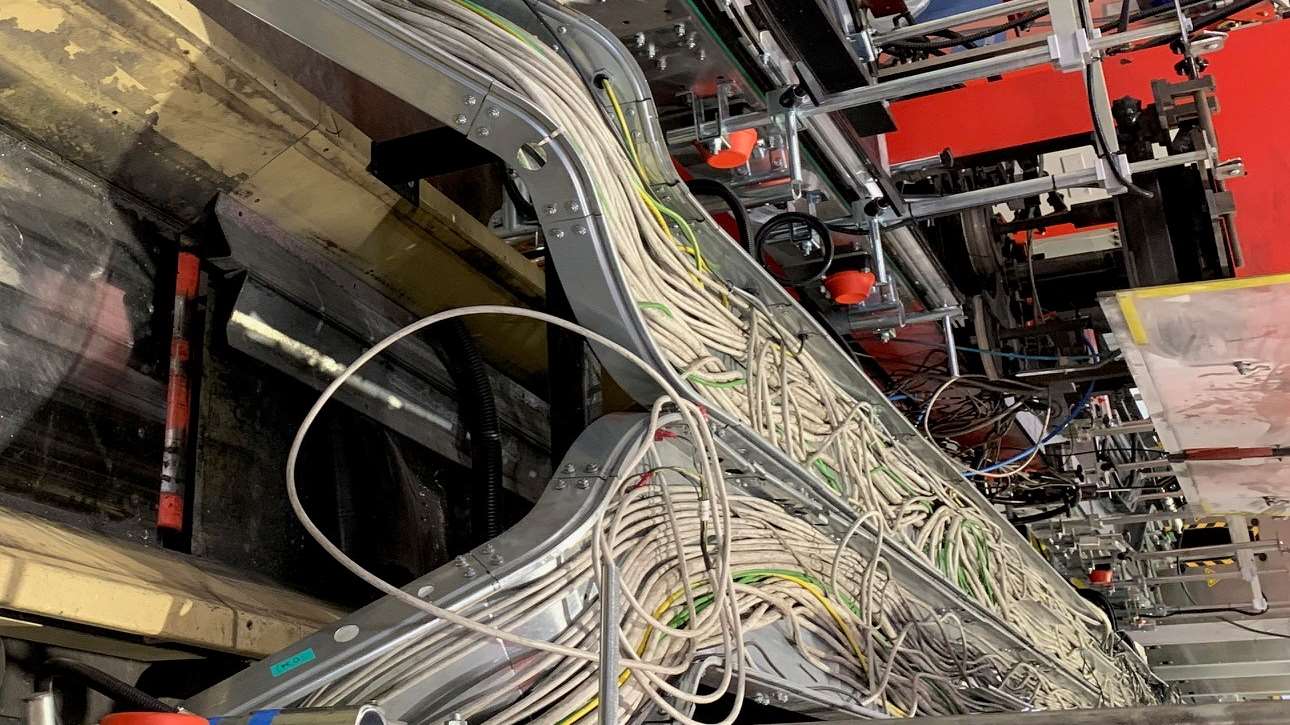

Feeder structure

New testing machines at the cold end

New machine with overhead cooling A brand-new utilisation concept for the white glass lines in Pöchlarn and Kremsmünster was developed in order to make maximum use of the two Austrian white glass furnaces and optimise line utilisation at both plants. In Kremsmünster, the line was also converted for triple-gob production, meaning that items with large batch sizes can now be moved from Pöchlarn to Kremsmünster. The Pöchlarn white glass line has been redesigned so that in return, suitable items can now be relocated from Kremsmünster to Pöchlarn. These changes enable us to better meet the increasing demand for white glass.

Reconstruction of feeder

The large-scale renovation work on the white glass line 4 in Pöchlarn began on 21 September 2020 with the demolition of the fireproof material on the feeder and the entire infrastructure. The fireproof material on the feeder was replaced, equipping it for the higher tonnage required. The line's machine bed was lowered, which also adjusted the incline of the annealing furnace. Working on the line is now much more ergonomic for the employees.

Occupational safety increased

The installation of a blank side barrier system minimises the risk of reaching into the station while it is in operation. The good view of the operating status remains unchanged. The Pöchlarn plant is the first in the Vetropack Group to be equipped with this safety system. The installed lubricating robot is the newest of its kind.

Modernisation at the cold end and modern project management

Four new Symplex testing machines recognise the binary mould code of the glass containers via the barrel camera. Pleats and bubbles on the body of the container are easier to detect and any mould-related errors are reported to the hot end in real time using images. An update of both Check+ testing machines, four glass orientators and new glass scanners at the packer to detect shards of glass on the pallet complete the new infrastructure on white glass line.

This website uses cookies to ensure you get the best experience on our website.Privacy statement

- Sustainability Report

- Col1

- Col1

- Col1

- Col1

- Material Topics and Performance Review